TORSION SPRINGS

TORSION SPRINGS

Torsion springs work by torsion or twisting. As the spring is twisted it applies a resistive torque. This torque increases at a linear rate. Torsion springs should always be designed so that the force or torque causes the spring to tighten (i.e. if the torsion or twisting action is in a clockwise direction the spring should be anti-clockwise or left-hand wound.) They can be used in the other direction but the operating stresses are likely to cause problems.

These springs can have an endless number of leg designs. These fall into the three categories of tangential legs, radial legs and axial legs. In addition, torsion springs can be single (with one coiled body) or double (with the two helical bodies connected by a central leg) and can be closed or open coiled.

There are a wide range of uses for torsion springs, and are normally used over a mandrel. JB Springs can manufacture and supply a wide range of torsion spring from small torsion springs used in electrical equipment and hinges to larger torsion springs used in agricultural equipment.

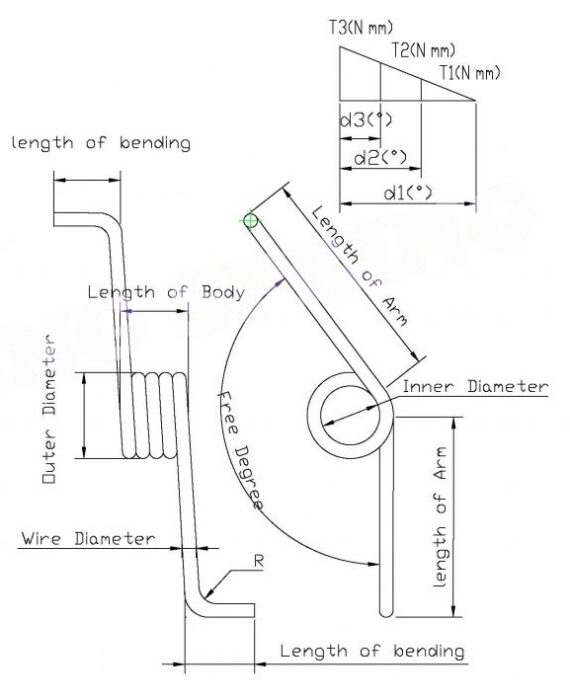

Torsion Spring Parameters

Following are the parameters required for manufacturing accurate design of Tension Springs :-

- Diameter of Shaft / Rod where the spring is to be fit over , as the torsion spring Inner Diameter gets reduce during working .

- Diameter of Bush /Hole where the spring is to be fitted .

- Application dimension / space , as during loading/working condition the leg length of the spring increases .

- Rotation and force required as per application .

- Frequency / Cycles required for operating spring .

- Application which will helps to select the Material /Surface Finish for resistance of corrosion .

- Application of the spring which will helps to choose the loop ends .

Torsion Spring product range

- Wire Diameter ranging from 0.15 mm-10 mm.

- In all square ,rectangular and round wire.

Previous

Next