PRODUCTION FACILITES

COILING

Precision coiling of springs on the finest imported machines incorporating the world renowned coilers from Walfios, Schenker, De Merwede . A wide range of wire of wire diameters are coverd from 0.1 mm to 16 mm. Highly skilled, foreign trained operatives have been inducted to carry out this primary manufacturing operation.

TEMPERING

Modern conveyorized stress relieving and other heat treatment furnaces with close control of temperature facilitates consistency in bulk production of precision springs. the furnaces has been specially designed by our collaborators.

GRINDING

Spring end grinding being one of the most critical manufacturing operation. Imported electronically controlled grinding machines from OMD, Italy, has been installed, High accuracy of length and load with automatic grinding wheel wear compensation is guaranteed by these machines. Uniform surfacing of spring ends ensures maximum quality in end squareness and parallelism.

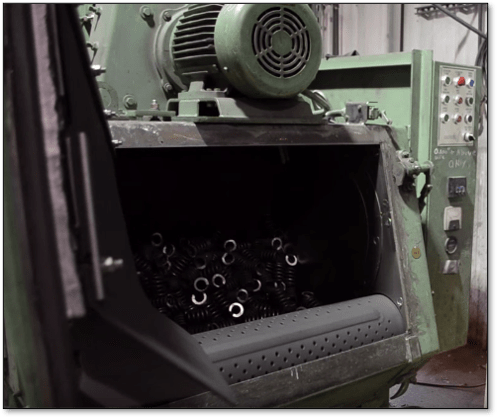

SHOT PEENING

Superb shot peening machines to impart beneficial macro stresses to improve the fatigue life of springs subjected to alternating loads in addition to imparting excellent surface finish.

SPRING TESTING

Our Spring match the highest standards in the world. testing machines for compression, tension, torsion and fatigue have been imported from INDIA, and few specially designed and manufactured by our collaborators. capable of testing any parameters of spring design.

THE LAST WORD

People and machines working in harmony. always alert. committed to consistent quality. a commitment that begins with the purchase of the raw-materials, and continues down the production line, to give you an extraordinary range of precision springs. no compromise on quality whatsoever.